Please click on the questions in order to read the answers.

There are generally 4 types of known Jumbo bags. Following are the types and usages of FIBC bags:

Jumbo A (Regular FIBC)

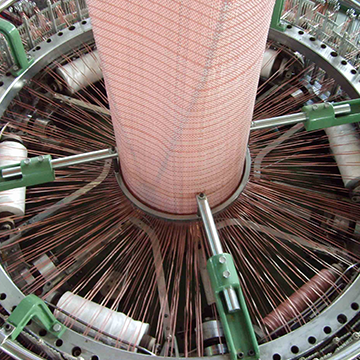

Regular Jumbo Bags are manufactured from regular PP fabric by adopting a special technique to keep the fabric break down. Jumbo Bags are cost effective solution for bulk packing. They are mainly used for chemicals, fertilizers, fiberglass, food products, seeds, peanuts, starch, grains, mining, construction, pigments, plastics, and other agricultural products.

(ii) Jumbo B (Anti-static Bag)

The polypropylene fabric is woven with special conductive tape. This provides continuous and effective collection of charges through all points. Conductive straps are used with ground tabs to ensure grounding. Voltage less than 6 kv as per standard IEC 61340 4 – 4. Electrostatic charges are conducted to the ground via conductive tape, eliminating static discharges from the bags when grounded.

It is mainly used for chemicals, fertilizers, fiberglass, food products, seeds, peanuts, starch, grains, mining, construction, pigments, plastics, and other agricultural products.

(iii) Jumbo C (Earth Conductive Bag)

These bags are made from fine conductive threads. An antistatic bag, or conductive bag, is a shipping bag for electronic devices, which can be affected by electrostatic.

These plastic bags normally and have a distinctive color according to its properties:

* The polyethylene model can also be made as foam or bubble wrap, either as sheets or bags.

To create the anti-static effect, the black bags or silver bags are slightly conductive, forming what is known as a Faraday Cage around the item to be protected avoiding any discharges from being deposited onto the protected devices as the bags are handled.

(iv) Jumbo D (Dissipative Bag)

It is a special type of bag that doesn’t store static electricity. Static is deadly to electronics. Dissipative properties should be tested as per standard IEC / ISO 61340- 4 – These bags are used to transport flammable powders, when flammable or gas present around the bag.

Disclaimer: Weather, Product and other un-forcible factors may give different results. Please do due diligence at your end as some restrictions may apply.